Understanding Today’s Technical Driveshaft Differences

Tomorrow's Technician

MAY 15, 2025

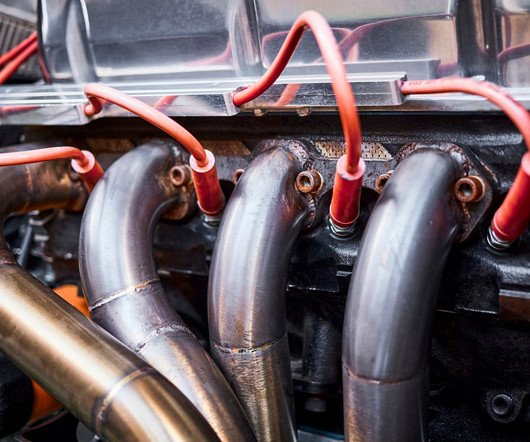

Always follow manufacturer guidelines, use correct torque specs on fasteners, and ensure proper phasing on slip-yoke driveshafts. The post Understanding Today’s Technical Driveshaft Differences appeared first on Tomorrows Technician. However, the materials and engineering behind this component have advanced considerably.”

Let's personalize your content