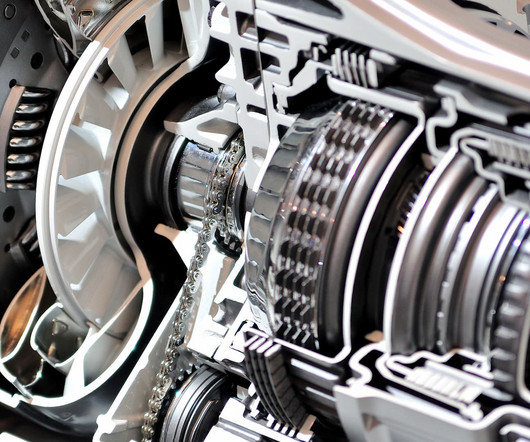

Transmission Fluid Hydraulics

Brake & Front End

FEBRUARY 26, 2025

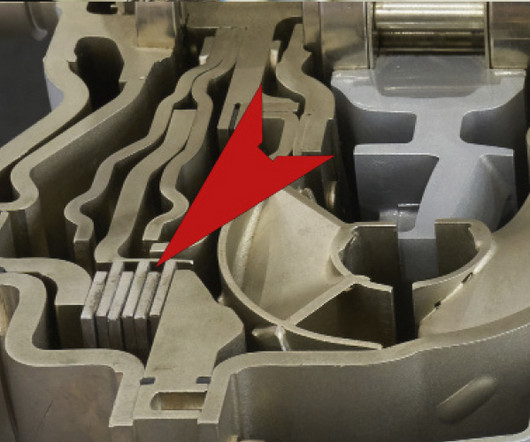

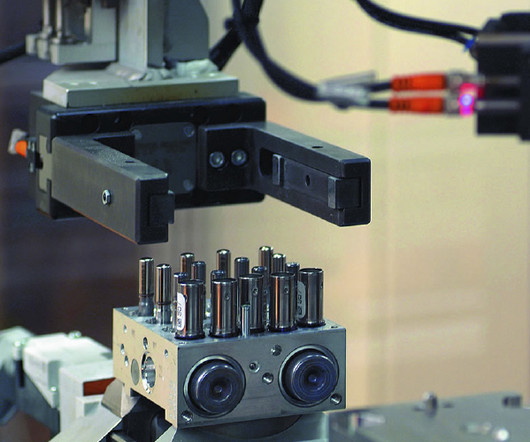

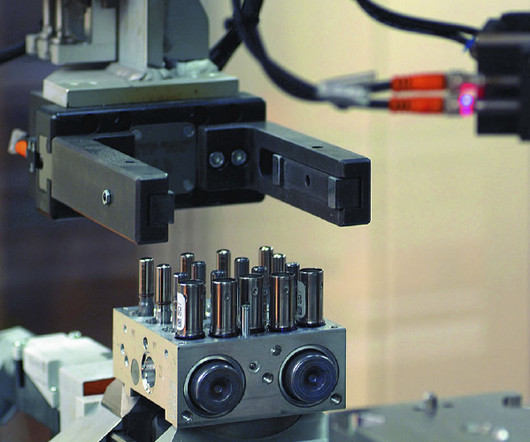

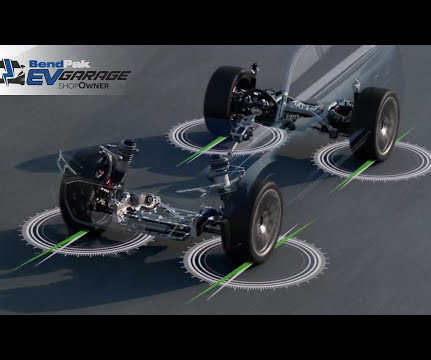

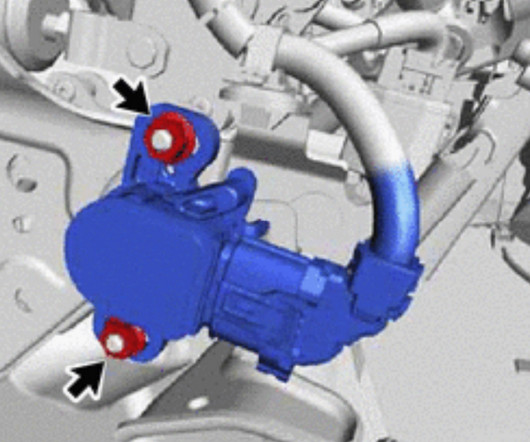

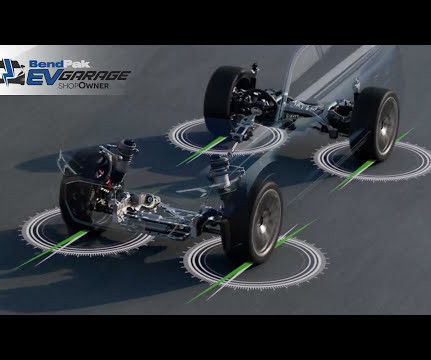

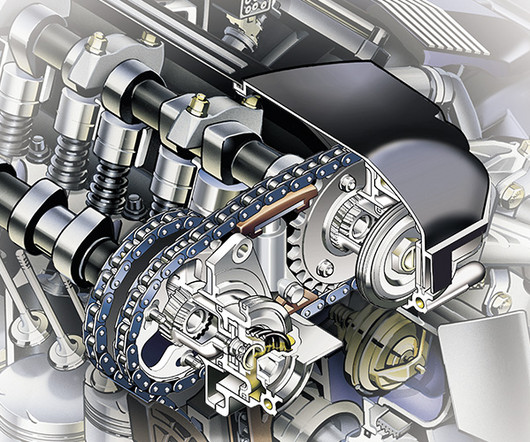

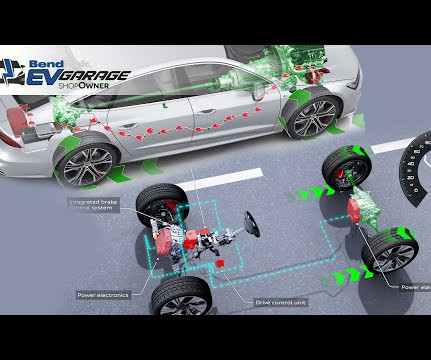

Transmission Fluid Hydraulics and Shifting To understand why using the correct transmission fluid is necessary, you first have to know how the transmission fluid flows inside an automatic transmission. This is basic hydraulics. Fluid Paths The journey starts in the pan. After the pump comes a valve or valves that do two things.

Let's personalize your content