What is a misfire? Is a misfire when the cylinder does not fire? Is it when the cylinder fires too soon or too late? The answer is “yes” to both questions. Some misfire complaints are a flashing check engine light, and a P0300 to P0312 diagnostic trouble code (DTC) indicates that one or more cylinders are misfiring. This is the easiest misfire to diagnose. But, what if there are no codes and a misfire is intermittent? This is where it gets complicated.

Occasional misfires may pass unnoticed, but a steady misfire is hard to miss. The engine usually feels rough, lacks power and uses more gas than usual. Sometimes a misfire may feel like a vibration. Unfortunately, a misfire also will cause a considerable increase in hydrocarbon (HC) emissions, which can cause a vehicle to fail an emissions test.

The crank sensor is the key component in determining a misfire. The PCM calculates the time between the edges of the crank reluctor wheel teeth by receiving a signal from the CKP sensor. Then, the crankshaft rotational velocity and acceleration are compared in the event of a power loss from each cylinder.

When a power loss is less or more than the calibrated value, the suspected cylinder is determined to be misfiring by the PCM. The misfire detection is enabled after certain base information is received by the PCM. Typically, the engine coolant temperature, cylinder head temperature, intake air temperature and, if equipped, the mass air flow sensor (or a combination of these) are used to evaluate the condition and the crank and cam positions.

The OBDII system will identify the cylinder(s) that are not contributing their normal dose of power and set a code corresponding to the firing order. It will count the misfires from a cylinder. Once the misfires hit a specific threshold, a misfire code will be set.

A P0303 code, for example, would tell you that the No. 3 cylinder is misfiring. To figure out which cylinder is No. 3, refer to a diagram of the engine’s firing order or look for markings on the intake manifold, spark plug wires or ignition coils (if the engine has a coil-on-plug ignition system).

The misfire monitor runs only when the conditions are right. For example, if the engine is in open-loop operation, it might not run the misfire monitor. Some more sophisticated powertrains might even suspend the misfire monitor if the transmission torque converter is about to lock. Some might turn it off when the A/C clutch is engaged.

The misfire monitor also looks at the total number of misfires from all the cylinders. If the total number of misfires exceeds a set value, it might take measures to limit damage to the catalytic converters by adjusting timing and altering the fuel trims.

Generic, Global and Enhanced

When OBDII was being standardized, it did two things. First, it allowed automakers to update emissions calibrations in the field. Second, it permitted emissions regulators to test the emissions and confirm that a vehicle is performing as it should.

These emissions protocols are called monitors. There are monitors for just about every emissions-related sensor or system on the vehicle. Mode $06 is where this information for the monitors resides.

Most monitors are pass or fail. Continuous monitors run all the time. Non-continuous monitors test when the conditions are optimal, like when the engine is at a specific coolant temperature, or the throttle is at a set angle.

Some aftermarket scan tools can access Mode $06 with enhanced OBD, global or generic modes. These modes can take the hexadecimal data from the monitors in Mode $06 and translate them into misfire counts and monitor information.

What are you looking for? First, a misfire count for a specific cylinder needs to be compared to the other cylinders. If one or more cylinders have a high number of misfire events, that is the cylinder you should investigate. Knowing the specific cylinder, you can focus your tests on the ignition coil, fuel injector or mechanical components. You also can try other scan tool tests like power balance or the deactivation of an injector and/or ignition coil.

WORN SPARK PLUGS

Every time a spark fires, the spark burns a few metal molecules off the plug’s electrodes. Over time, this eats away the electrodes and rounds off their sharp edges. The erosion gradually increases the gap between the electrodes, increasing the firing voltage required to generate a spark. Eventually, the ignition system reaches a point where it fails to produce enough voltage and the plug misfires.

MECHANICAL ISSUES

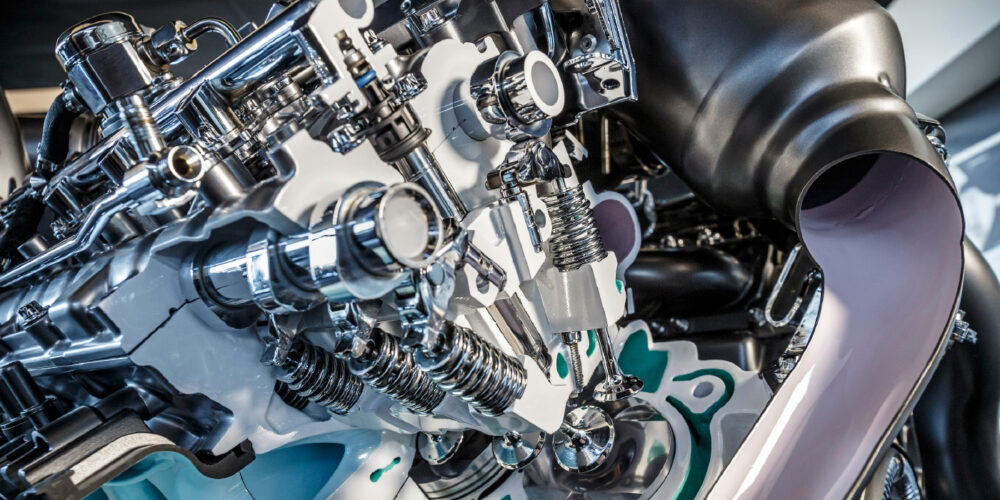

The components of the valvetrain can cause misfires. Any issues with the valves not opening at the correct time or with enough lift can cause a misfire. This can be caused by damaged variable valve timing actuators, compressed lifters or wear on the camshaft lobes.

Another issue can be a loss of compression that can cause a misfire. This can be caused by burned valves, worn piston rings or even a leaking head gasket.

FUEL INJECTORS

A condition known as “lean misfire” can occur with insufficient fuel in the combustion chamber. Lean misfire causes that affect only one cylinder include a dirty fuel injector, an open or shorted fuel injector, or a problem in the fuel injector driver circuit (wiring or PCM).

Another fuel injector issue could be a leaking injector. The leaking fuel into the cylinder could foul the spark plug in the short term. If the leaking injector persists, it can wash the oil from the cylinder walls and cause a loss of compression.

VACUUM LEAK

A vacuum leak into the intake port of the cylinder in question can cause a lack of fuel. Vacuum leaks on individual cylinders commonly occur around intake port gaskets or vacuum hose connections. Insufficient valve lash, a broken piston ring or a leaking cylinder head gasket can cause a partial loss of compression. Depending on where the vacuum leak is on the manifold, it can generate random or specific cylinder misfire codes.

Tackling a misfire is not about one part or procedure. When the fuel and air mixture ignites in the cylinder, eight or more changing factors have to be met for the combustion event to pass the misfire monitor. Throwing parts at the problem in hopes it will resolve the misfire will typically result in multiple comebacks for the customer.