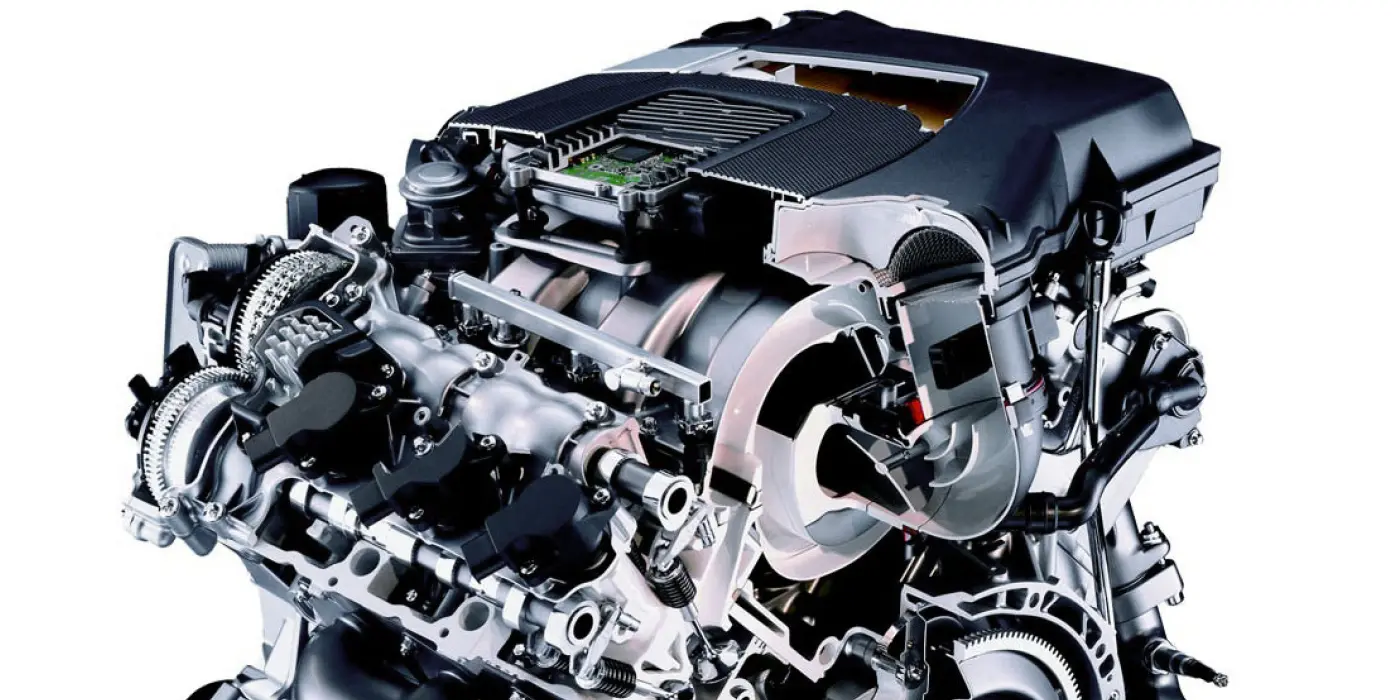

Have you ever had a customer come into your shop complaining that their vehicle is telling them their battery needs to replaced or that stop/start has been disabled? This is becoming more common as vehicles and battery management systems become more sophisticated.

On all stop/start vehicles, the life and performance of the battery are measured by the vehicle in several ways. These constant checks prevent the engine from being stopped and the battery from not having the power to restart. Some manufacturers call it a battery or power management system but, whatever its name, the goal of the system is to balance the load on the alternator and battery. Most of all, these monitoring steps prevent the customer from being stranded.

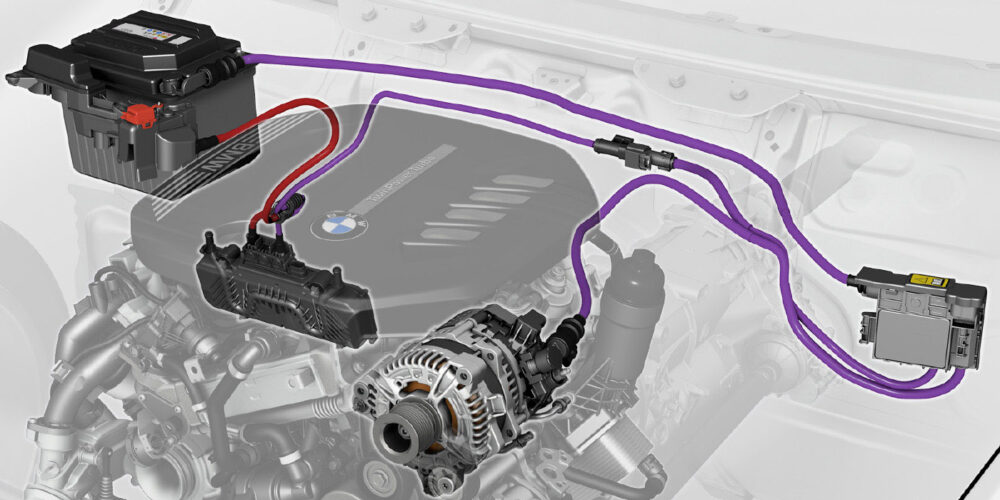

Most stop/start systems can use current-measuring sensors in the battery cables and will look at the electrical loads on the vehicle. Some more advanced systems will have connections on the positive and negative battery terminals that measure the internal resistance.

All systems also look at voltage drop during cranking. If the voltage drops too low or for too long, it will set a code and turn on the battery light in the instrument cluster.

Most systems use sensors to measure the temperature of the battery. Sensors can be on or inside the battery, and some systems have the temperature sensor in the positive battery cable. If the engine control module is mounted near the battery under the hood, the temperature sensor in the module will be used to estimate battery temperature.

Why is battery temperature important? A battery contains a chemical reaction that is sensitive to hot and cold. If a battery is cold, the chemical reaction between the plates and acid occurs slower, and less power is available. If a battery gets too hot, it could damage the capacity of the battery to store energy.

With a scan tool, it is possible to see data PIDs that indicate the life of the battery and the outputs of the sensors related to the condition of the battery. Some codes can be set for the battery and the sensors and also have monitors and parameters.

The diagnostic strategy for the battery and electrical system requires research to see how the system measures battery life and performance. You will need to confirm the condition of the battery using a tester.

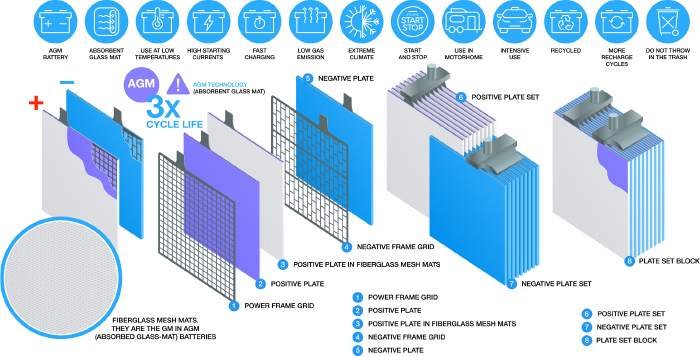

Most stop/start systems use a deep cycle aggregated glass mat battery (AGM) or advanced flooded battery. This type of battery requires different testing methods and shop chargers than conventional standard flooded lead-acid batteries.

Don’t just use a voltmeter to determine the state of charge: voltage readings can be different for AGM batteries. Due to differences in internal construction, AGM batteries have lower internal resistance when compared to a conventional lead-acid battery. AGMs can charge faster and recover faster after starting the engine. Also, AGM batteries perform better at colder temperatures.

More sophisticated battery testers can take these internal engineering features into account. Some vehicles use a second battery to handle non-starter loads, so the occupants don’t notice any disruption to the HVAC or audio systems when the engine is off.

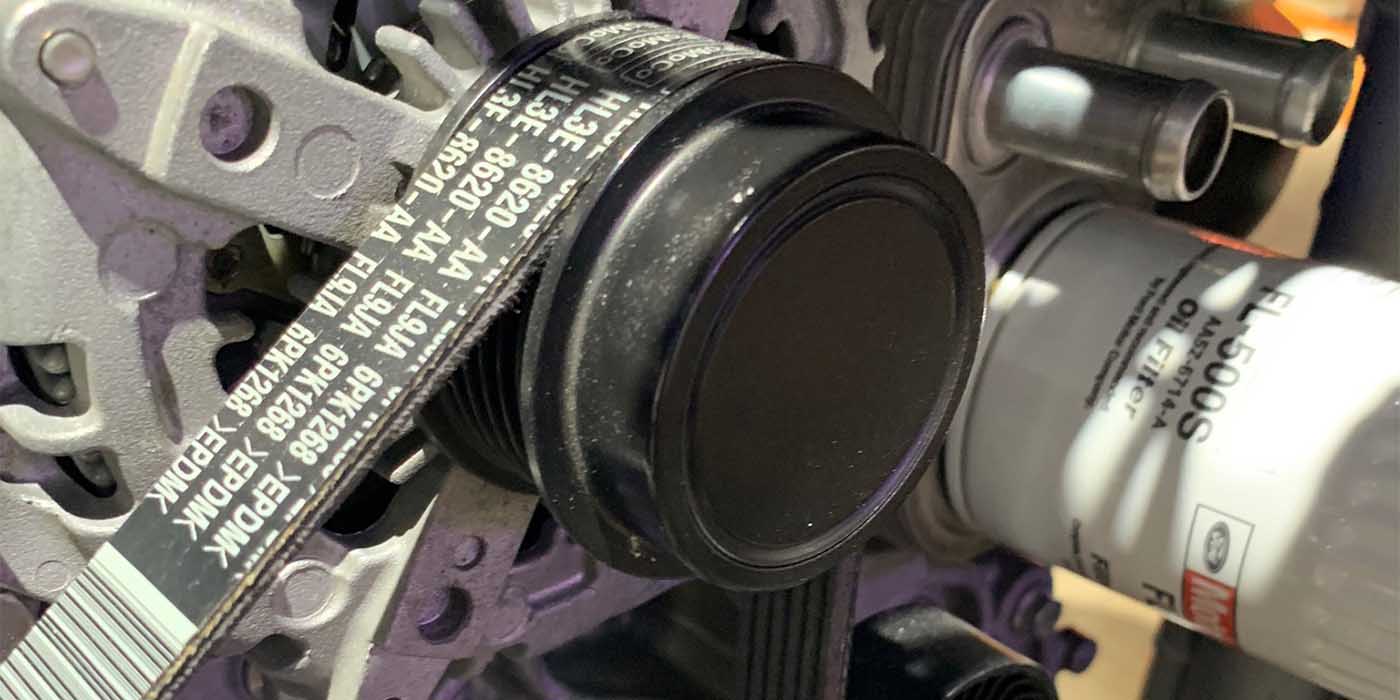

Never take a new battery for granted. Often, customers will install a battery on their own or have a battery replacement performed at retail auto parts or “big box” store. The battery may fit, but it will likely be a conventional flooded battery instead of an AGM, or the specification for cold-cranking amps or reserve capacity will not match the vehicle. If you see a new battery, test it and make sure it is the correct battery for the application.

The other diagnostic area for inspection is the battery cables. Many have sensors mounted on the positive battery terminals. Also, most terminals will have more than one wire, typically leading to a power distribution module under the hood. If the connection to the battery is compromised by poor installation or corrosion, it can cause codes or the stop/start system to be deactivated.